News

Stay connected with the pulse of the maritime world and Marine Lite’s journey. Our Newsroom combines the latest updates in global maritime trends, marine technology, and shipping innovations with exclusive insights into our company’s milestones, achievements, and developments.

From Greece’s ports to international waters, discover the stories shaping the industry and Marine Lite’s role in navigating its future.

How Often Must Marine Safety Signs Be Replaced? | Regulatory Guidance

Is there a mandatory replacement period for marine safety signs?

No.

International maritime regulations do not define a fixed time-based replacement interval for marine safety signs.

Instead, regulations require that safety signs remain:

- Legible

- Visible

- Correct in content and placement

- Effective under normal and emergency conditions

Replacement is therefore condition-based, not age-based.

___________________________________________________________

What do SOLAS regulations require?

According to the SOLAS Convention, particularly Chapter II-2 (Fire Protection, Detection and Extinction), ships must display appropriate safety signs to support:

- Fire safety

- Means of escape

- Emergency response

- Passenger and crew guidance

SOLAS focuses on availability and effectiveness, not on the age or manufacturing date of signs.

___________________________________________________________________________________________________________________________________________________

What role do IMO guidelines play?

IMO instruments and circulars support SOLAS by:

- Defining standardized symbols and layouts

- Requiring consistency across vessels

- Ensuring recognisability in emergency situations

They do not establish a replacement timeline. Compliance is assessed based on correct application and condition.

______________________________________________________________________________________________________________

Do ISO standards define when signs must be replaced?

No.

Relevant ISO standards include:

- ISO 7010 – Safety signs and symbols

- ISO 17398 – Photoluminescent safety markings

- ISO 3864 – Design principles for safety signs

These standards define:

- Design criteria

- Color and contrast

- Luminance and visibility requirements

They require that signs meet performance criteria, but do not specify a lifespan.

___________________________________________________________________________

Why is a 5-year replacement period often referenced?

The 5-year period is not a regulatory requirement.

It is commonly referenced because:

- Photoluminescent materials may gradually lose performance

- Five years often aligns with dry-docking or major refit cycles

- Operators frequently conduct full safety signage reviews at this interval

This should be understood as a maintenance benchmark, not a legal obligation.

_________________________________________________________________________

When must marine safety signs be replaced?

A marine safety sign should be replaced if it:

- Is no longer legible

- Shows fading or loss of contrast

- Does not meet photoluminescent performance requirements

- Is physically damaged (cracks, peeling, deformation)

- Displays outdated or non-compliant symbols

- No longer corresponds to the vessel’s layout or escape routes

Age alone is not sufficient justification for replacement.

_______________________________________________________________

How often should marine safety signs be inspected?

| Inspection Activity | Common Practice |

| Visual condition check | During routine safety rounds |

| Compliance review | During statutory surveys |

| Photoluminescent performance review | At dry-dock or refit |

| Full signage assessment | Commonly around 5 years |

Inspection intervals may vary depending on vessel type and operating conditions.

____________________________________________________________________________

Do Port State Control inspections check the age of safety signs?

No.

Port State Control inspections focus on:

- Visibility and legibility

- Correct symbols and wording

- Proper placement

- Effectiveness during emergency conditions

The manufacturing or installation date is not an inspection criterion.

_______________________________________________________________

Are photoluminescent signs affected by time?

Yes.

Performance may be affected by:

- UV exposure

- Humidity

- Cleaning chemicals

- Mechanical wear

For this reason, visual inspection and performance evaluation are more reliable than age-based assumptions.

___________________________________________________________________________________________________

Who is responsible for deciding replacement?

Replacement decisions are typically made by:

- Ship Owners

- Ship Operators

- Technical Managers

- Safety Officers

Decisions are based on:

- Inspection findings

- Surveyor observations

- Regulatory updates

- Internal safety management procedures

_____________________________________________________

Summary

| Topic | Key Point |

| Fixed replacement interval | Not defined |

| SOLAS / IMO requirement | Condition-based |

| ISO standards | Performance-based |

| 5-year reference | Industry practice |

| Replacement trigger | Legibility and compliance |

|

|

|

Regulatory References (Non-Exhaustive)

- SOLAS Convention, Chapter II-2

- IMO safety signage guidelines and circulars

- ISO 7010 – Safety signs and symbols

- ISO 17398 – Photoluminescent safety markings

- ISO 3864 – Safety sign design principles

References are provided for contextual guidance and should be interpreted alongside statutory surveys and flag state requirements.

Editorial Note

This article is provided as technical guidance based on:

- International maritime regulations

- Applicable ISO standards

- Practical experience with vessel inspections and safety signage

It does not replace statutory requirements, flag state rules, or surveyor judgment.

Low Location Lighting (LLL) systems on passenger ships – SOLAS requirements, testing and measurement

Low Location Lighting (LLL) systems are a critical safety feature on passenger ships, designed to assist passengers and crew in identifying escape routes when normal or emergency lighting becomes ineffective due to smoke conditions. The performance of these systems is regulated through international conventions, IMO resolutions and ISO standards, which define both installation requirements and verification through testing and measurement.

This article provides a technical overview of Low Location Lighting systems on passenger ships, focusing on regulatory requirements, system characteristics and the inspection, testing and documentation process.

What is a Low Location Lighting system

A Low Location Lighting system is installed close to deck level and is intended to clearly indicate escape routes in reduced visibility conditions. By positioning the guidance line below the main smoke layer, LLL systems remain visible even when conventional lighting is obscured.

On passenger ships, LLL systems form part of the vessel’s overall evacuation strategy and are designed to provide continuous visual guidance along corridors, stairways and exits leading to muster stations and embarkation areas.

Low Location Lighting on passenger ships

Passenger ships carrying more than 36 passengers are subject to specific requirements for Low Location Lighting systems. These systems are installed to ensure that passengers can readily identify escape routes during an emergency, particularly in scenarios where smoke reduces the effectiveness of overhead lighting.

The operational objective of LLL on passenger ships is not decorative or supplementary, but functional: to maintain route recognition under emergency conditions and support orderly evacuation.

Low Location Lighting SOLAS requirements

The installation and performance of Low Location Lighting systems on passenger ships are governed by the 1974 SOLAS Convention, as amended. In particular, relevant provisions include:

- SOLAS Chapter II-2, Regulation 28

- SOLAS Chapter II-2, Regulation 41-2

In addition, IMO Resolution A.752(18) provides guidelines for the approval, installation and maintenance of Low Location Lighting systems. These guidelines define minimum performance criteria for photoluminescent materials, including luminance levels and duration of afterglow, ensuring that the system remains effective during evacuation.

Photoluminescent Low Location Lighting systems and strips

Many Low Location Lighting systems on passenger ships are based on photoluminescent (PL) materials. These materials absorb ambient light during normal operation and emit visible light when external illumination is lost.

Photoluminescent Low Location Lighting strips are typically installed along escape routes, stair landings and changes of direction. Their effectiveness depends on several factors, including material properties, exposure to adequate charging light and correct installation geometry.

The performance of photoluminescent systems cannot be assessed visually alone and requires measurement against defined standards.

Testing and measurement of Low Location Lighting systems

Testing and measurement of Low Location Lighting systems are mandatory to verify compliance with IMO Resolution A.752(18) and applicable SOLAS regulations. Inspections focus on confirming that the installed system meets the minimum luminance requirements and maintains visibility for the required duration.

Measurements are carried out in accordance with ISO 15370, which defines the methodology for assessing photoluminescent materials used in Low Location Lighting systems. Typical measurements include luminance values recorded at defined time intervals after removal of the activating light source, commonly at 10 and 60 minutes.

Testing is performed on board under controlled conditions and focuses on areas with the lowest levels of ambient illumination, ensuring that system performance is verified under conservative assumptions.

Documentation and inspection reports

The outcome of LLL testing and measurement is documented in an inspection report, which forms part of the vessel’s safety documentation. These reports typically include:

- Identification of tested locations

- Description of installed LLL materials

- Measurement conditions and equipment used

- Recorded luminance values and pass/fail evaluation

- Reference to applicable standards and resolutions

Such documentation is required by classification societies and may be reviewed during statutory surveys and inspections.

Approved service suppliers for LLL testing

Testing and inspection of Low Location Lighting systems may be carried out by service suppliers approved by classification societies. Marine Lite Printing SA is approved as a Lloyd’s Register Service Supplier for inspections of photoluminescent Low Location Lighting systems and evacuation guidance systems used as an alternative to low location lighting.

This approval is conditional upon compliance with documented procedures, calibrated measurement equipment and qualified personnel, ensuring that inspections are carried out in accordance with applicable international standards.

Low Location Lighting systems play a vital role in passenger ship safety by providing reliable visual guidance during emergency evacuation scenarios. Compliance with SOLAS requirements and IMO guidelines is verified through systematic testing and measurement, supported by documented inspection reports.

Understanding the regulatory framework, system characteristics and testing methodology is essential for ensuring that Low Location Lighting systems continue to perform as intended throughout the vessel’s operational life.

Wrapping up IMPA London 2025!

Wrapping up IMPA London 2025!

Wrapping up IMPA London 2025!

Two days of great exchanges and connections at Booth 92.

The exhibition may be over, but the discussions continue — safety, reliability, and innovation remain at the core of what we do.

We were proud to share the stand with Martechnic GmbH, joined by Traconed B.v. | Safety At Sea and Alfa Marine Safety, making Booth 92 a strong point of collaboration.

A special thanks to IMPA for honoring our 20th anniversary with a commemorative plaque — a milestone we’re proud to celebrate within the maritime community.

IMPA London 2025 - Exhibition Stand in Progress

Exhibition Stand in Progress

Exhibition Stand in Progress

As we prepare for IMPA London 2025, we're reminded of thereal value of meeting in person.

Conversations. Connections. Shared ideas.

Conversations. Connections. Shared ideas.

Exhibitions like IMPA London provide a focused environment to present our work, engage with industry developments, and listen to what the sector truly needs.

We’ll be there — at Booth 92, alongside our partner Martechnic GmbH — and we’re getting ready to showcase what’s next!

We’ll be there — at Booth 92, alongside our partner Martechnic GmbH — and we’re getting ready to showcase what’s next!

Marine Lite at IMPA London 2025 | Booth 92

Marine Lite to Exhibit at IMPA London 2025

Marine Lite Printing SA is pleased to confirm its participation in IMPA London 2025, the leading IMPA exhibition for the global maritime supply chain. The event will take place on 9–10 September 2025 at the QEII Centre in Westminster, bringing together key players in maritime procurement.

Sharing Booth 92 with Martechnic GmbH

We will be sharing Booth 92 with our trusted partner, Martechnic GmbH, a recognised name in onboard technical solutions. Together, we look forward to welcoming attendees, exchanging ideas, and contributing to important conversations shaping the future of maritime procurement and safety.

What we offer

We specialise in IMO-compliant safety signage and photoluminescent materials that help keep vessels safe, visible, and regulation-ready.

Trusted worldwide, our solutions support safety at sea—day and night.

Why IMPA Attend London

IMPA London offers a focused platform to connect, exchange expertise, and follow the latest developments in maritime supply.

Visit Us at Booth 92

Whether you’re exploring new partnerships or seeking reliable, regulation-ready signage solutions, we look forward to seeing you at Booth 92 on 9–10 September 2025 at the IMPA London exhibition.

The Critical Role of Food-Related Signage on Ships

On board any vessel, food safety is paramount. With a diverse and often cramped environment, clear signage is essential for maintaining proper hygiene standards in food preparation areas. Adequate food-related signage on ships helps prevent contamination, ensure safe food handling, and comply with international safety regulations.

On board any vessel, food safety is paramount. With a diverse and often cramped environment, clear signage is essential for maintaining proper hygiene standards in food preparation areas. Adequate food-related signage on ships helps prevent contamination, ensure safe food handling, and comply with international safety regulations.

From “Please Wash Only Food Equipment Here” to “All Handlers of Food Must Wash Hands After Visiting the Toilet,” each sign serves a distinct purpose. These signs guide crew members to perform specific actions that reduce the risk of foodborne illnesses. Signs related to hygiene, like those indicating handwashing after using the restroom, are especially critical in enclosed ship environments, where the spread of bacteria and pathogens can be faster.

Moreover, signs such as “No Plastic or Food Waste” and “Food Waste Only” contribute to environmental sustainability, ensuring that food waste is handled correctly and does not contribute to marine pollution. Shipboard food waste management is a necessary part of minimizing the vessel’s environmental footprint, and clear, understandable signage helps enforce proper practices.

Food preparation zones must be clearly defined, with signs like “Food Preparation Area: Raw Food Only” ensuring that food safety protocols are followed rigorously. This reduces the risk of cross-contamination, which can lead to foodborne diseases. Proper separation of raw and cooked food, as well as the restriction of certain practices to designated areas, is crucial in preventing hazardous situations.

In conclusion, food-related signage on ships is not merely a regulatory requirement; it is a necessary part of maintaining the health and well-being of all individuals on board. By promoting safe practices, these signs help ensure that food preparation and waste management adhere to the highest standards, creating a safe environment for all who work and travel at sea.

Ensure Compliance with the Best Food Safety Practices on Your Vessel!

✔️ IMO-Approved Signs

✔️ Clear and Durable

✔️ Easy Installation

Our high-quality food-related signage helps your crew adhere to hygiene standards and regulations with ease. Browse our extensive collection of food safety signs and posters, designed specifically for the maritime environment. Trust Marine Lite Printing SA to keep your vessel safe and compliant.

Explore our products:

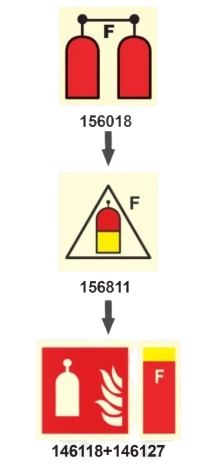

Signage Updates: Previous and Revised Designs

At Marine Lite, we are committed to keeping our signage offerings up to date with the latest industry standards. Our latest catalogue now features a detailed comparison of old and updated signage designs and codes, ensuring clarity and compliance with current regulations.

This comprehensive resource allows you to explore the evolution of our signage solutions, highlighting key improvements in design, functionality, and compliance. Whether you’re replacing outdated signs or looking for updated options, our catalogue is designed to meet your needs.

Discover the updates and maintain safety excellence onboard.

Visit our catalogue now to learn more!

Find Updated Signs & Posters, Plus New Services in Our Latest Catalogue

We are pleased to announce that our updated Marine Lite Printing catalogue is now available on our website.

This edition introduces essential updates to our safety signs and posters, fully aligned with the latest standards,

alongside exciting new services to better meet your maritime safety needs.

Raising the Standard: Tracey Montgomery's Article on Essential Guidelines for Maritime Safety Signage in IMPA Magazine

We’re pleased to announce that Tracey Montgomery, Co-Owner of Marine Lite Printing SA, shares her expertise in an insightful article featured in the latest IMPA Magazine - Supply Chain and Sustainability, the official publication of the International Marine Purchasing Association (IMPA). Drawing on years of experience in marine safety, she addresses the vital considerations for selecting signage that meets high safety standards in the maritime industry.

Emphasizing the importance of regulatory compliance, the use of approved materials, and close collaboration with safety officers, this article provides procurement professionals with a practical guide to equipping vessels with signage designed for durability, visibility, and alignment with current regulations. These insights ultimately contribute to safer, more efficient operations at sea.

This piece serves as a valuable resource for those involved in the procurement and maintenance of maritime safety equipment, offering guidance on making informed choices that enhance onboard safety for crews and passengers alike.

Read the full article and gain a deeper understanding of best practices in marine safety signage here.

Is Your Vessel’s Low Location Lighting (LLL) System Up-to-Date? Why Regular Renewal is Vital for Maritime Safety

Is Your Low Location Lighting (LLL) System Up-to-Date? The Need for Superior Solutions and Regular Renewal for Maritime Safety

Why is Low Location Lighting (LLL) essential for your vessel?

In emergencies, Low Location Lighting (LLL) systems are vital for guiding passengers and crew to safety. These systems illuminate escape routes at ground level, ensuring clear visibility during power outages or smoke-filled conditions. Keeping your LLL up-to-date improves safety and ensures compliance with IMO and SOLAS regulations.

Why is it important to renew and update LLL tapes and components?

Over time, LLL systems degrade due to exposure to harsh marine environments, resulting in wear and corrosion. Regular renewal is essential to maintain effectiveness, ensuring that your systems meet ISO 15370 standards. Replacing worn components prevents safety risks during emergencies and avoids costly regulatory fines.

How do our LLL tapes and components enhance safety?

Our LLL solutions provide continuous, reliable visibility along escape routes. Designed for maritime conditions, our tapes and components meet the highest standards, ensuring safe and efficient evacuation.

Why invest in LLL systems today?

Choosing our LLL products means investing in long-lasting, compliant solutions. Our systems enhance evacuation safety, reduce maintenance costs, and ensure your vessel is ready for emergencies.

Choose us for superior LLL solutions.

Our products offer unmatched durability and performance. Trust us to provide expert support and top-quality safety equipment for your vessel.

|

|

|

||||||||||||||||||